Etching systems for etching dental implants

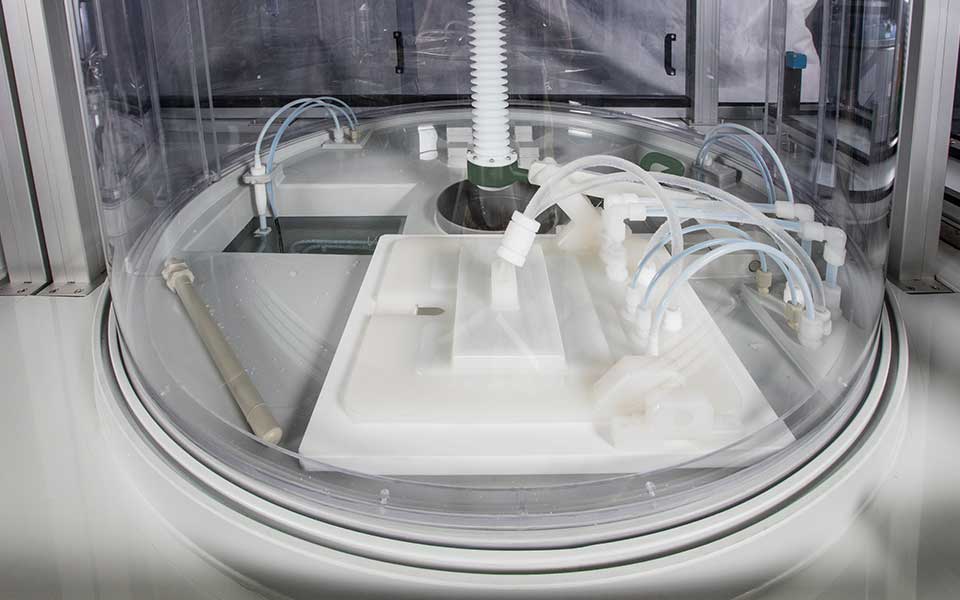

Semi-manual or fully automatic etching systems from KKS are used specifically for acid etching of dental implants. The modular principle of these systems allows individual and customer-specific combinations of different etching processes (single or double etching) with subsequent rinsing and drying, plus a direct cleanroom connection for automatic etching systems. KKS etching systems are characterized by high system and process reliability and guarantee safe and reproducible surface quality.

Masking during blasting and etching

Masking during the blasting and etching of dental implants is process-critical. The “masking strategy” is therefore a key success factor for process stability, product quality and thus for cost-effectiveness in the production of dental implants. On the one hand, masking serves to protect the internal geometry of the implants, while on the other hand, it also helps in automating production processes.

KKS develops product-specific masking for its customers, for both blasting and etching.

Special features of KKS etching systems for acid etching

KKS etching processes and etching systems

With more than ten years’ experience of process development and production of etching systems, KKS helps implant manufacturers worldwide to optimize these quality-relevant surface processes.

With our own state-of-the-art etching system in the Medical Surface Center, we offer etching of dental implants as a successful outsourcing service, from development to process validation. This know-how also flows directly into the development and realization of customer-specific etching systems.

Features of KKS etching systems

- Safe media handling

- Reproducible processes

- Equipment qualification (DQ/IQ/OQ)

- Computer system validation of equipment (CSV)

Options and accessories:

- DI water treatment

- Heating systems (continuous-flow water heaters, heat exchangers)

- Dehumidification modules for effective drying at low temperatures

- Neutralization unit for air and water

Outsourcing services in the Medical Surface Center for blasting and etching

For many years, KKS has offered customers all over the world blasting and etching of dental implants in the Medical Surface Center as an outsourcing service. By linking the automatic etching system in the Medical Surface Center to a cleanroom of cleanroom class ISO 7, KKS not only guarantees its customers the highest levels of cleanliness and process reliability, but also offers the option of primary packaging directly after etching. Naturally, color anodizing and final cleaning of other components for the dental industry are also possible.

Peripheral Equipment

Whether you require system peripherals such as DI water treatment, integrated heating systems (continuous-flow water heaters, heat exchangers), dehumidification modules for efficient drying, or neutralization systems for contaminated exhaust air and wastewater: KKS offers suitable peripheral equipment for etching systems that supports and guarantees safe and efficient process flows.