Ultrasonic transducers for ultrasonic systems

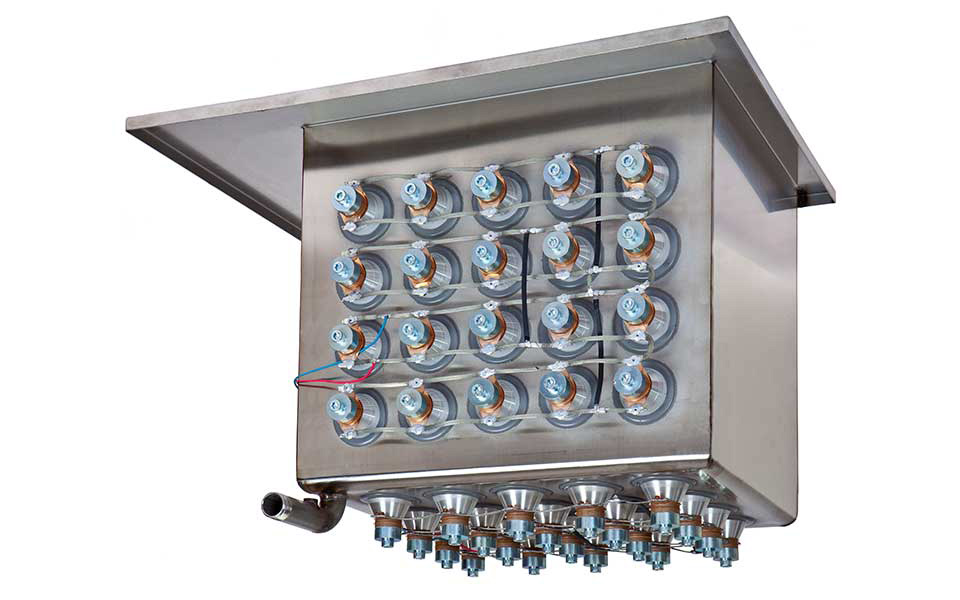

An ultrasonic transducer contains a number of ultrasonic elements connected in parallel depending on the required power. This assembly converts the electrical vibrations generated by the generator into mechanical vibrations via piezo elements.

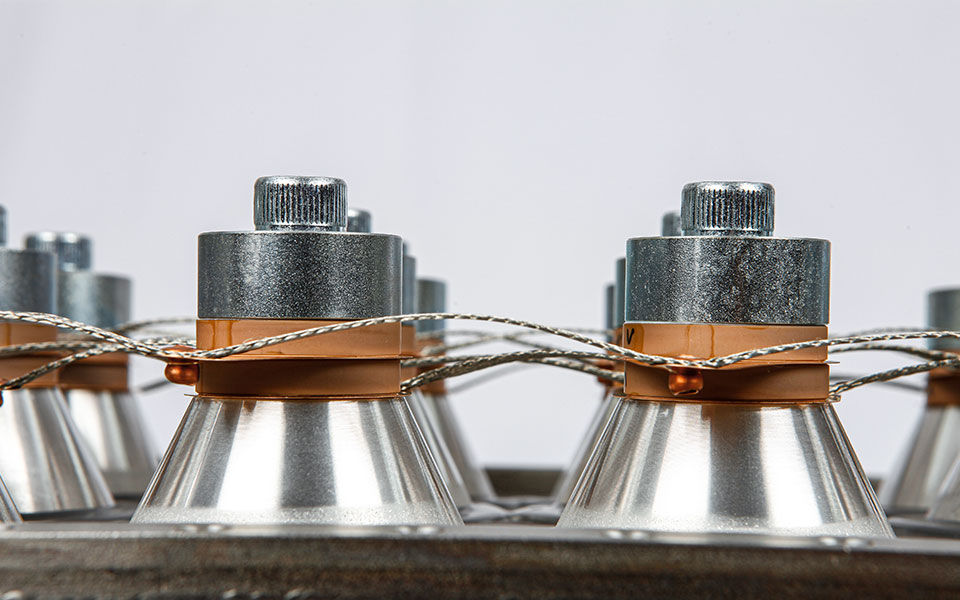

KKS ultrasonic elements are characterized by their long service life, operational reliability and consistent power output. They consist of two piezo elements that are mechanically pre-tensioned by two metallic end pieces.

The vibrations are transmitted to a stainless steel membrane by coupling parts. The deflection of the membrane surface causes the liquid media in the cleaning tank to vibrate, creating a homogeneous sound field.

High performance ultrasonic transducers

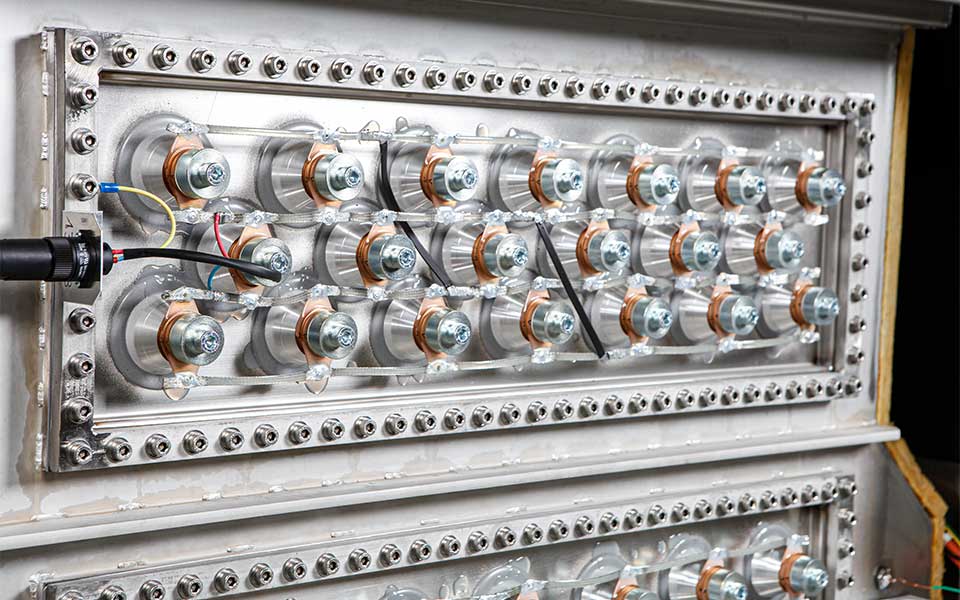

As elements for transmitting sound waves to the cleaning media, ultrasonic transducers or ultrasonic oscillation systems have a decisive influence on the performance and process reliability of an ultrasonic cleaning system. KKS’s core competences include the manufacturing of customized ultrasonic oscillation systems of any size and performance class. In its ultrasonic oscillation systems, wherever possible, KKS uses duplex stainless steel for the highest resistance to cavitation erosion. Our ultrasonic transducer systems excel by reason of their long service life and very high power output.

Directly equipped tanks – for the highest purity requirements

For cleaning systems with especially stringent cleanliness requirements (for example in the medical technology industry), the tanks are directly equipped with ultrasonic elements. As a result, the tank itself functions directly as an oscillating membrane. This provides advantages such as an optimized tank volume, less likelihood of impurities adhering to the tank itself and maximally efficient ultrasonic cleaning. Rounded corners assist bath maintenance and system cleaning. For maximum cleaning efficiency, ultrasonic elements are often attached to the bottom and at the same time to a side of the tank.

Immersible transducers – robust and flexible ultrasonic transducers

Immersible transducers are suitable both for the initial equipping and for retrofitting of existing tanks.

Plate transducers – space-saving and highly efficient ultrasonic transducers

KKS plate transducers are durable and effective ultrasonic transducers attached to a stainless steel membrane. The plate transducers are flange-mounted in a recess in the cleaning tank using a space-saving weld-in/press-in frame. Their installation does not reduce the available tank volume. Ultrasonic transducers are therefore suitable both for initial fitting and for retrofitting of existing tanks.

Longlife ultrasonic transducers – maximum power density and service life

KKS longlife ultrasonic transducers feature an extremely robust design. The 5 mm thick ultrasonic membranes are exclusively manufactured from duplex stainless steel and are distinguished by their long service life.

Longlife ultrasonic transducers are the preferred solution where the following requirements have to be met:

- Highest power density requirements (watts/membrane surface area)

- Small installation space

- Entry of abrasive contaminants into the cleaning tank

- High mechanical demands

- Use in vacuum

The longlife ultrasonic transducers are available in different geometric versions: rectangular as immersible transducers or triangular as corner transducers.

Tailor-made and powerful systems and installations

Systems and installations focused on process reliability and cost-effective operation are our main priority when developing and realizing your ultrasonic cleaning solution. We guarantee the highest quality standards in our own equipment construction and ensure that proven expert teams are available to you at all times to meet every requirement.

Find out more about our expertise in equipment construction and get in touch with one of our surface treatment specialists via the contact form.

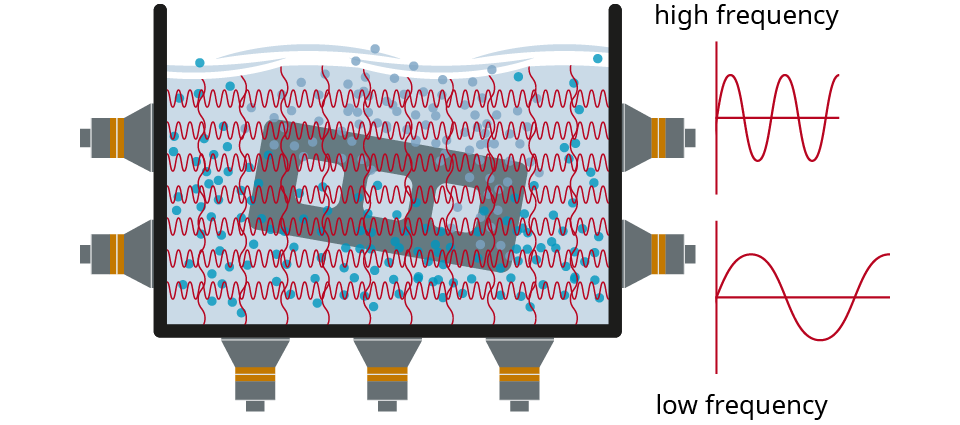

KKS ultrasonic transducer frequencies

KKS ultrasonic transducers can generate different frequencies when connected to corresponding ultrasonic generators. Excellent cleaning results can be achieved in a short time through sequential or simultaneous ultrasound treatment at two harmonic frequencies, such as 27 kHz and 80 kHz.

Frequency pairings

Applying the generated frequencies

Low frequencies of 27, 30 or 40 kHz

- Coarse cleaning

- Generate few but larger cavitation bubbles with a high implosion force

- Loosen persistent layers of dirt

High frequencies of 60, 80 or 100 kHz

- Fine and ultrafine cleaning

- Generate many but smaller cavitation bubbles with a high implosion force

- Loosen layers of dirt in the tiniest holes, delicate structures or porous surfaces

- Gentle to surfaces