Etching implants from the medical technology industry

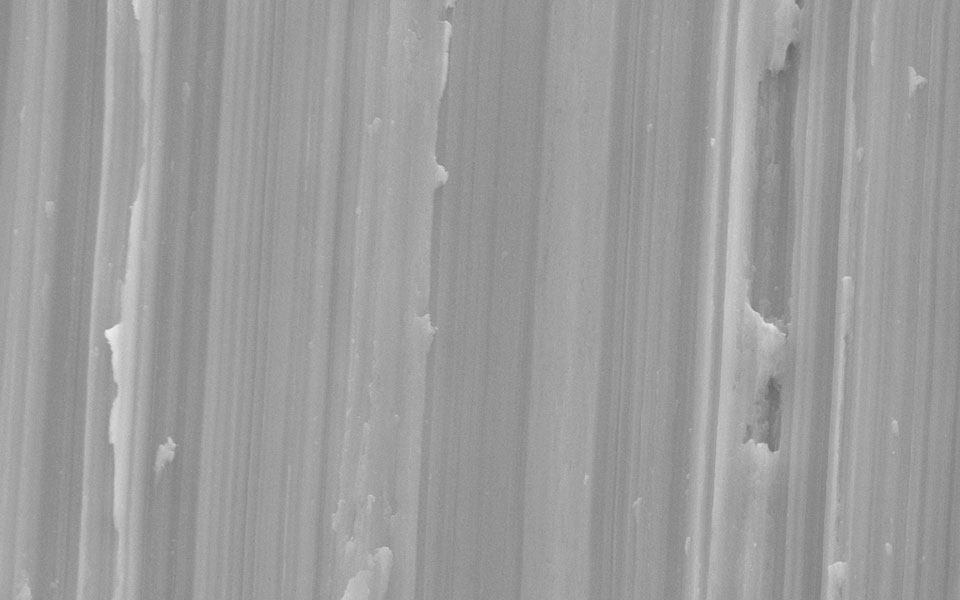

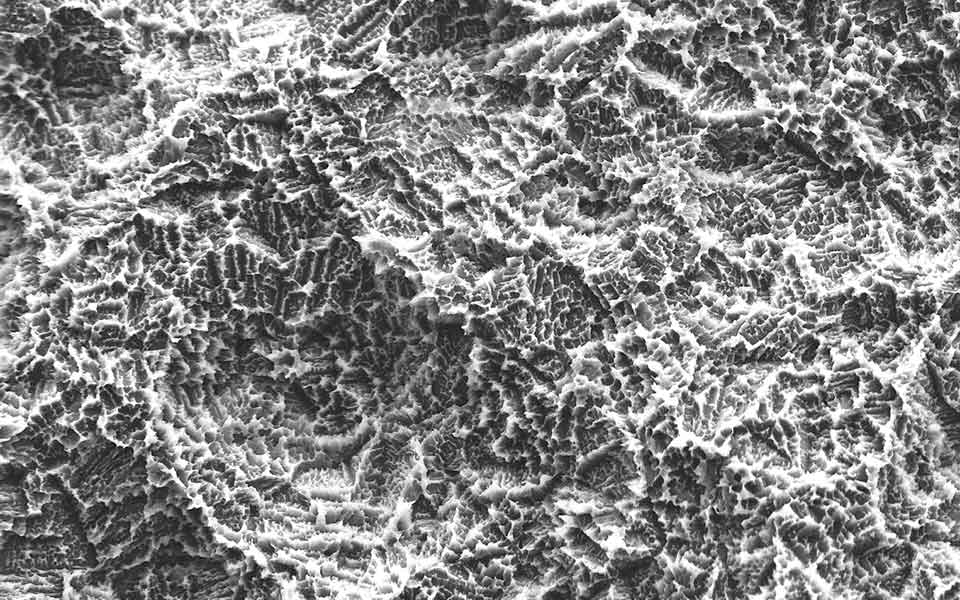

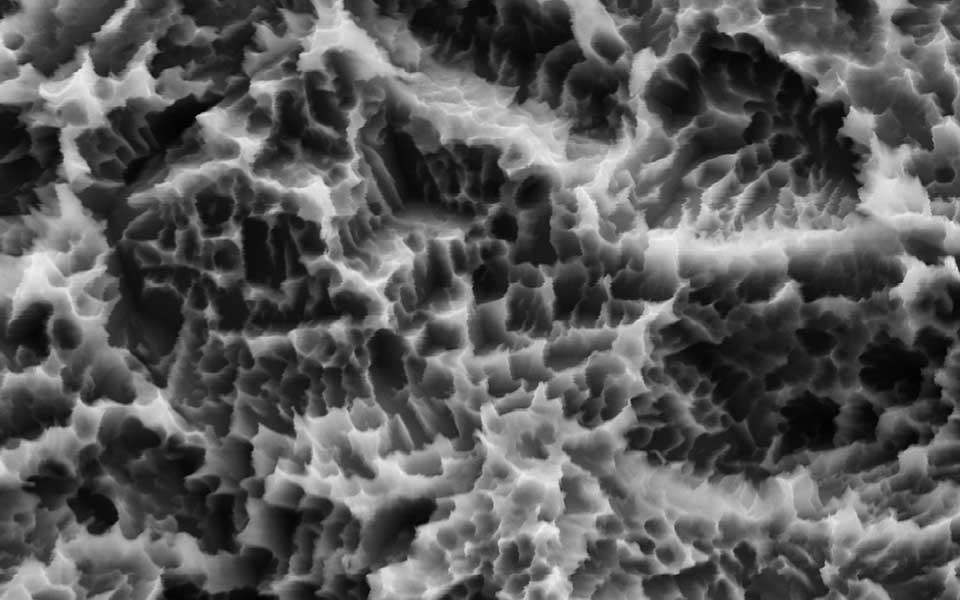

The etching of implants in the Medical Surface Center results in a highly roughened part surface that enables the ideal osseointegration. Etching in combination with corundum blasting represents a vital surface finishing step for achieving the required surface roughness; first corundum blasting creates a macrostructure and then the acid etching results in a microstructure.

Acid etching – areas of application

Dental implants acid etching – How it works:

Etching is a chemical process in which the metal oxide layer is dissolved and the titanium base material is very strongly chemically attacked. Sticking blasting particles still present on the surface from the previous blasting process are removed. Depending on the titanium alloy of the dental implants, KKS uses specific recipes of etching solutions. The microstructure on the surface of the implants is determined by the etching solution and process parameters such as time and temperature.

Etching for dental implants

Implants are etched using an immersion method. Targeted masking strategies ensure that the internal geometry and other defined implant zones are not attacked by affixing the implants to specific holders, immersing them in the etching solution and rinsing with ultrapure water after a defined etching period. Single or double etching processes can be used depending on the requirements, both executed by manual or automatic equipment.