Surface treatment in the medical technology sector

The medical technology industry places increasingly stringent requirements on the perfect surface of implants and medical instruments. However, surface treatment is gaining in importance in other areas too, including precision engineering and the watch-making industry. As an expert in surface treatment and ultrasonic cleanig, KKS is the ideal technology partner.

Thanks to our many years of experience developing surface treatment processes and systems for medical technology, watch-making and precision engineering sectors to name but a few, we can deliver the right solution for every requirement.

Our application-oriented approach to research and development guarantees that we are always at the forefront of technology – all with an added touch of Swiss precision. We are constantly developing and optimizing our services to meet the individual needs of our customers as well as researching new and perfected methods.

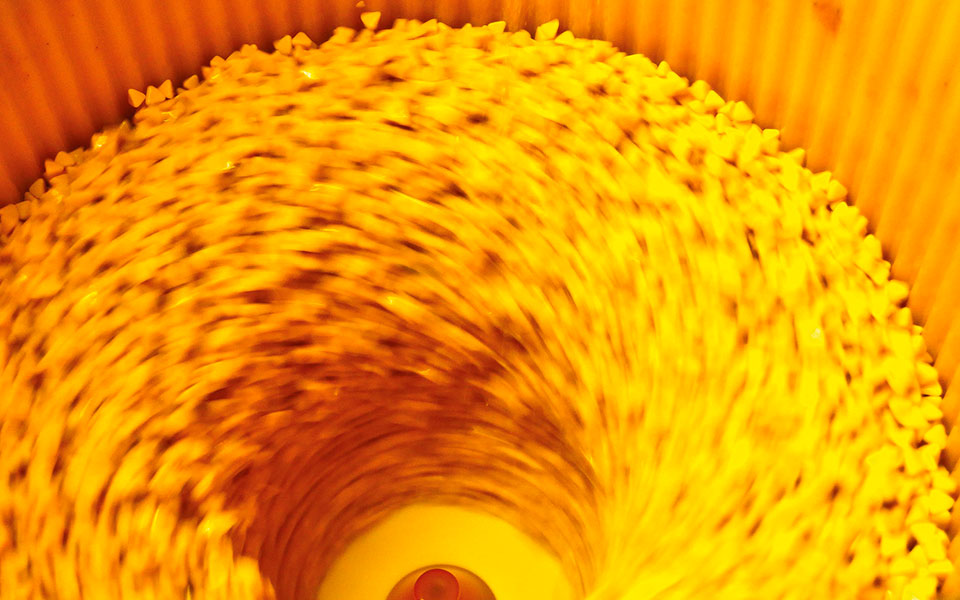

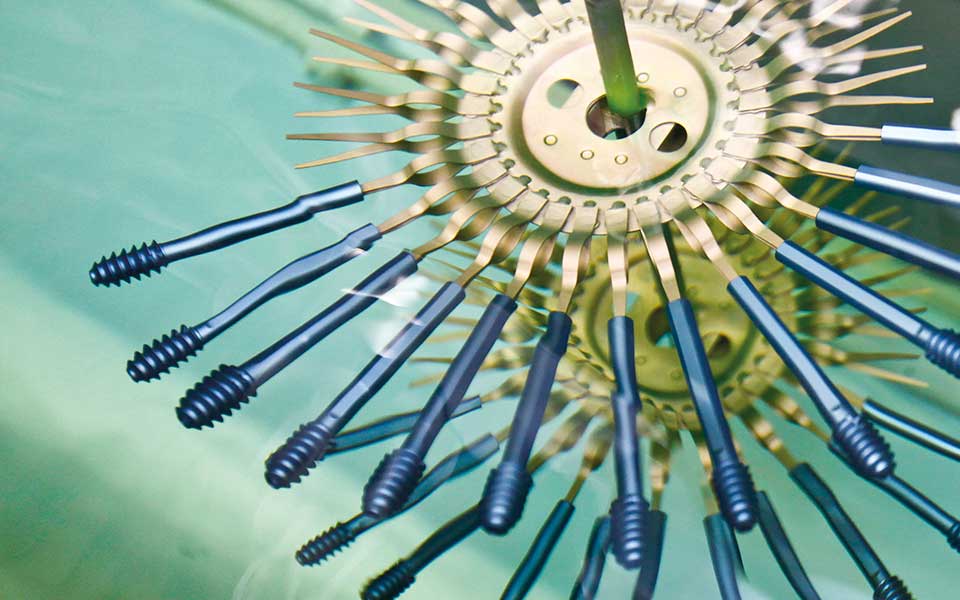

Mechanical processes

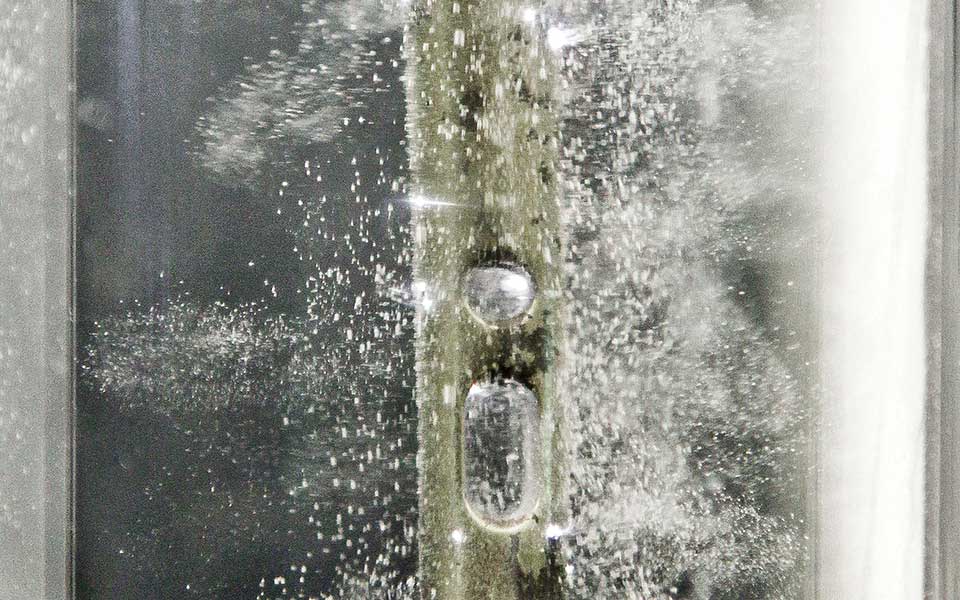

Chemical processes

Electrochemical processes

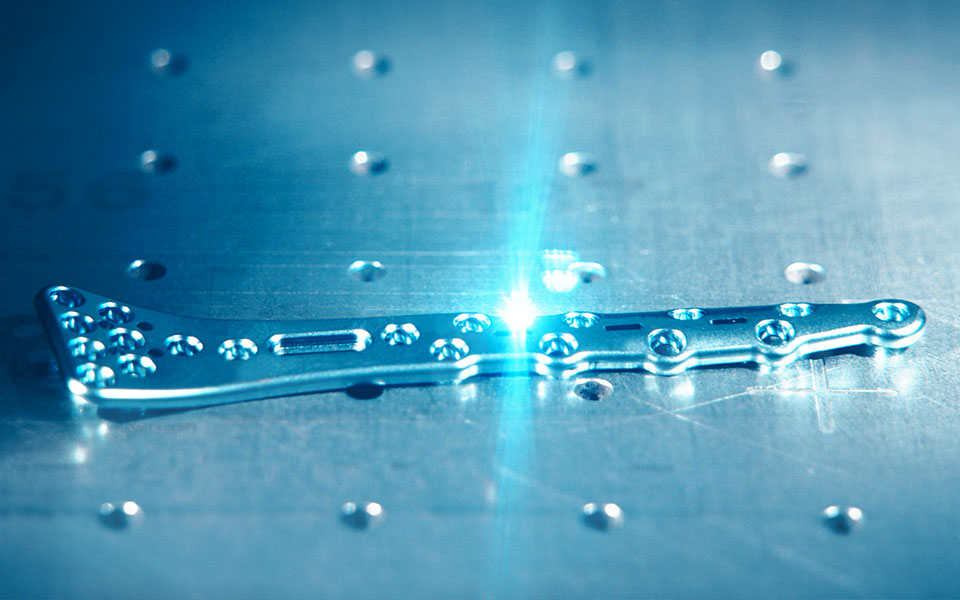

TioDark™ dark anodizing

- Biocompatible surfaces due to passivating oxide layer

- No change in component dimensions

- Excellent characteristics when it comes to microhardness, fatigue strength, scratch resistance and reduced abrasive wear

- Reduced content of critical alloy elements in the oxide layer

- Ready for easy laser marking

Systems, products and outsourcing services for surface treatment

In the area of our equipment construction we meet your needs for premium, high-performance and durable surface treatment systems with a combination of professionalism, passion, precision and technology. We ensure you can depend on the optimized conditions to meet complex requirements through the seamless qualification of systems.

At the KKS Medical Surface Center, we provide our customers with our entire know-how and state-of-the-art technologies for the optimal surface. From precise process definition through process development to surface treatment and final cleaning of medical implants, instruments and precision parts, which we offer as an outsourcing service at the highest level. Of course, product-specific, validated processes for cleaning and surface treatment are also available on request.

Equipment construction

KKS offers a complete range of systems for surface treatment and ultrasonic cleaning for a wide range of industries, including the watch-making, medical technology, precision engineering and electroplating sectors. Leading companies in each of these fields have chosen us as their technology partner on account of the exceptional qualities of our systems, including their durability and high levels of efficiency.

Products

Our products in the fields of ultrasonic technology, ultrasonic cleaning tanks, rinsing tanks and surface treatment systems enable us to meet every challenge involved in the ultrasonic cleaning and surface treatment of sophisticated products for the medical technology, watch-making, and precision engineering sectors to name but a few.

Medical Surface Center

KKS shares its entire technological expertise and passion for surface treatment with its global customer base in the form of an outsourcing service for surface treatment. Medical products and precision parts from various industries are cleaned and surface-treated. We also work together with our customers to devise custom processes for their current needs while continuously developing new and perfected surface treatment methods.