Automation of surface treatment processes

Stable and reliable system solutions are key elements in safe and powerful process systems. From the automation of an individual special tank through to the interlinking of several automatic systems via a superordinate control system, KKS offers solutions from a single source. A live superordinate control system can be viewed at any time in the KKS Medical Surface Center.

Whether certain process flows are executed manually or automatically, with linear transfer axes, rotary units or handling devices such as robots depends on various factors. Smaller quantities with varying geometries are often processed manually or partially automated. Full automation is more suitable for larger quantities, which significantly reduces the unit cost.

Our automation services at a glance

As a system manufacturer with the optimum level of vertical integration, KKS offers its customers intelligent automation solutions from a single source. These might be an integral component of an automatic process system or an overall system for supply technology including measuring and monitoring systems with the corresponding robotics.

Automation solutions tailored to the specific application

Throughout the course of a project, our design and automation specialists work in close collaboration with the customer to develop optimum solutions. Every step that is automated supports the perfect interplay between process steps and increases process reliability as well as production efficiency. Integrated monitoring systems ensure error-free and reproducible results. The perfect results from KKS process systems are based on the holistic consideration and implementation of individual requirements. We can offer advice on any problem.

Examples of successfully implemented automation solutions for surface treatment systems

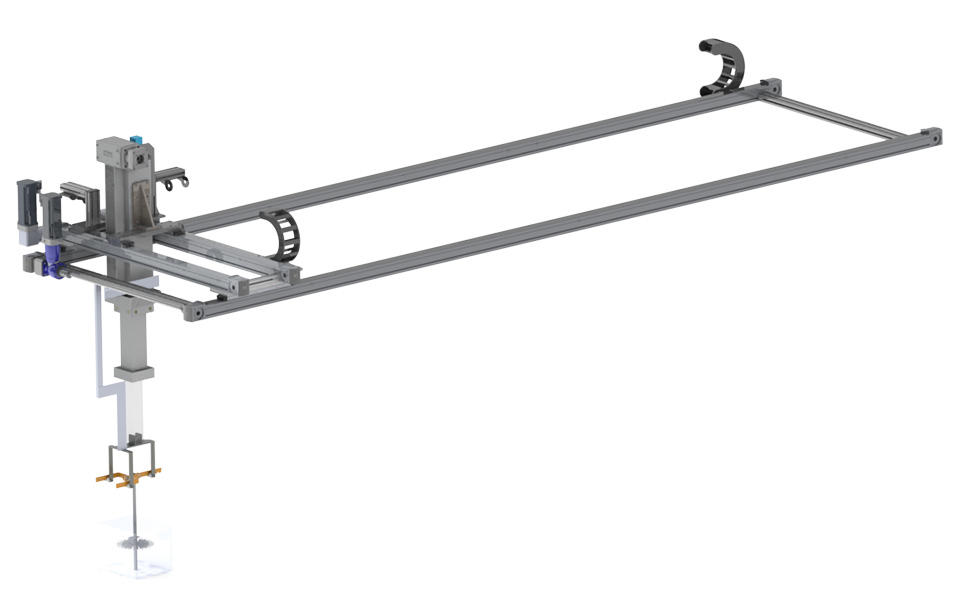

Linear 3-axis drive system with vertical telescopic axis

Space-saving 3-axis drive system implemented in a fully automatic anodizing system. The vertical telescopic axis reduces the system height. The process tanks can also be arranged in a space-saving layout thanks to the additional horizontal axis.

Workpiece holder oscillation and rotation

Multi-functional movement of goods implemented in a system for the final cleaning of parts in specific baskets (vertical oscillation) and as bulk material in barrels (rotation with vertical oscillation).

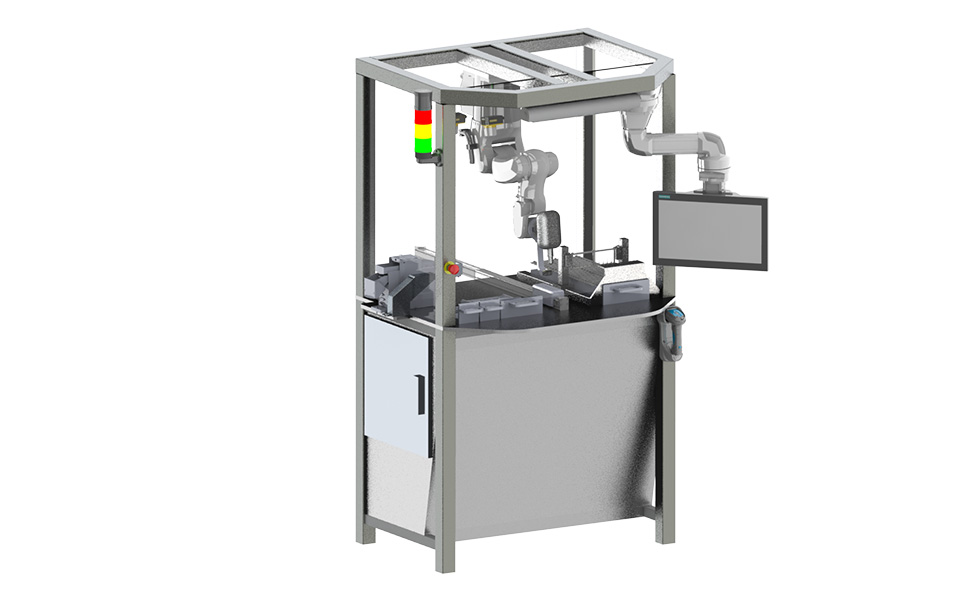

Automatic removal, masking and loading of workpiece holders

Multi-functional loading robot for removing products from the basket following preliminary cleaning, the masking of parts and reloading of the workpiece holders with the masked parts for the subsequent electrochemical process.