Pickling as a process in the medical technology sector

Pickling is always an essential step before the passivation of stainless steel parts if their natural passive chromium oxide layer is highly contaminated and compromised. This is rarely the case during the manufacturing of implants and medical implants, which usually do not require pickling. By contrast, titanium and titanium alloys always require pickling if electrochemical processes – such as color anodizing – or targeted material removal are to be carried out.

Pickling – areas of application

Pickling for the medical technology sector – How it works:

Pickling is a chemical process which dissolves metal oxide layers. In most cases, only hydrofluoric acid is suitable for this. We use different pickling solutions that contain hydrofluoric acid in combination with an oxidizing component. Different, targeted pickling solutions are used depending on the material, surface condition and required degree of surface material removal.

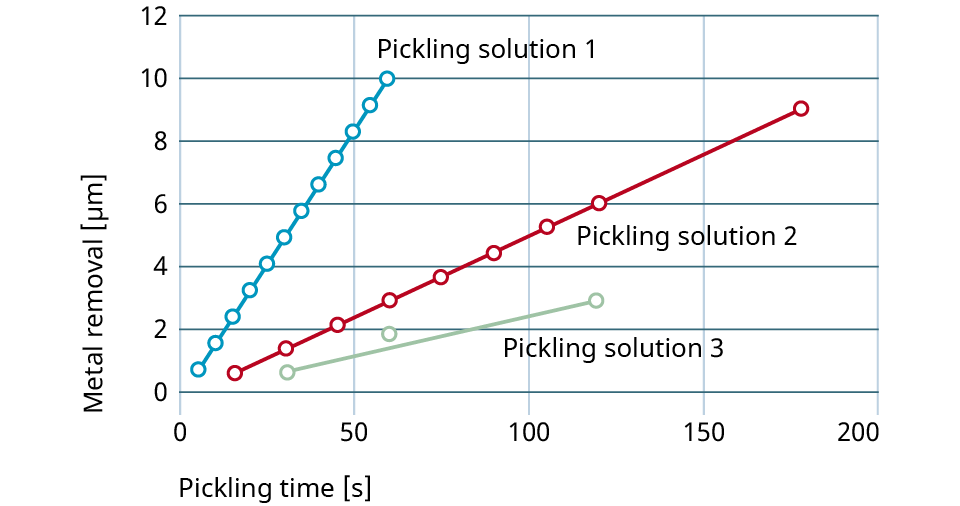

The extent of the material removal depends on the duration and type of pickling. After pickling, the clean and oxide-free titanium surface is in the ideal state to produce clear and bright colors across the entire TioCol™ anodizing process.

Pickling technology for medical technology

We use an immersion method for pickling titanium, whereby the parts are placed in a chemically resistant, coated basket or hanger and treated in a pickling solution. After pickling the parts are immediately rinsed with water supported by vertical basket oscillation. To avoid immediate spontaneous oxide layer building under normal atmospheric conditions, all of the necessary electrochemical processes follow straight after the pickling and rinsing step.