Color anodizing for implants – TioCol™

The “color coding” of implants and medical instruments made from titanium and titanium alloys is extremely useful to surgeons, both before and during surgery – it is much easier to distinguish between different types and sizes of osteosynthesis products, such as screws, wires, plates or intra-medullary nails when they are color coded. Medical products are color-coded in this way using the TioCol™ color anodizing process. Color-anodized titanium implants boast excellent biocompatibility regardless the color and the TioCol™ treatment also reduces the release of alloy elements from the titanium alloy. Implants and medical instruments with TioCol™ surfaces are ideal for laser marking – another very effective form of labelling products directly on the surface – before or after treatment.

Color anodizing TioCol™ – areas of application

Color anodizing titanium implants – How it works:

During the TioCol™ process, which is often used in the medical technology sector, colors appear caused by a titanium oxide layer, creating an optical interference effect: incident light is reflected on the surface of the oxide layer (actually colorless) and on the base layer. The overlap of the reflected light waves (interference) results in a colorful appearance of the surface.

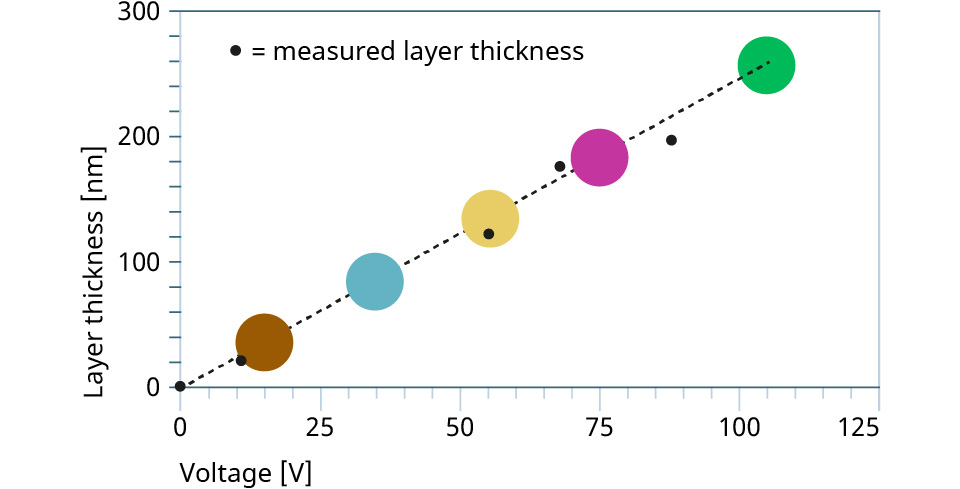

Different layer thicknesses result in different colors during color anodizing

Under normal ambient conditions, titanium spontaneously forms a 5 nm titanium oxide layer on the surface, which protects the base material against corrosion. There are many ways to increase this layer thickness. With TioCol™, for example, we use an electrochemical approach to produce a titanium oxide layer that measures up to 300 nm on implants.

Color anodizing using the TioCol™ method in a KKS color anodizing system in real time

TioCol™ color anodizing technology

Depending on the requirements, the implants are first pre-treated (mechanical pre-treatment, cleaning, pickling). The color-specific thickness of the titanium oxide layer is achieved electrochemically during the TioCol™ anodizing process by applying direct voltage.

For this, the implants are electrically connected across a rack and energized as an anode in an aqueous electrolyte. There is a linear relationship here between the electrical direct voltage applied and the thickness of the oxide layer as well as the resulting specific interference color.

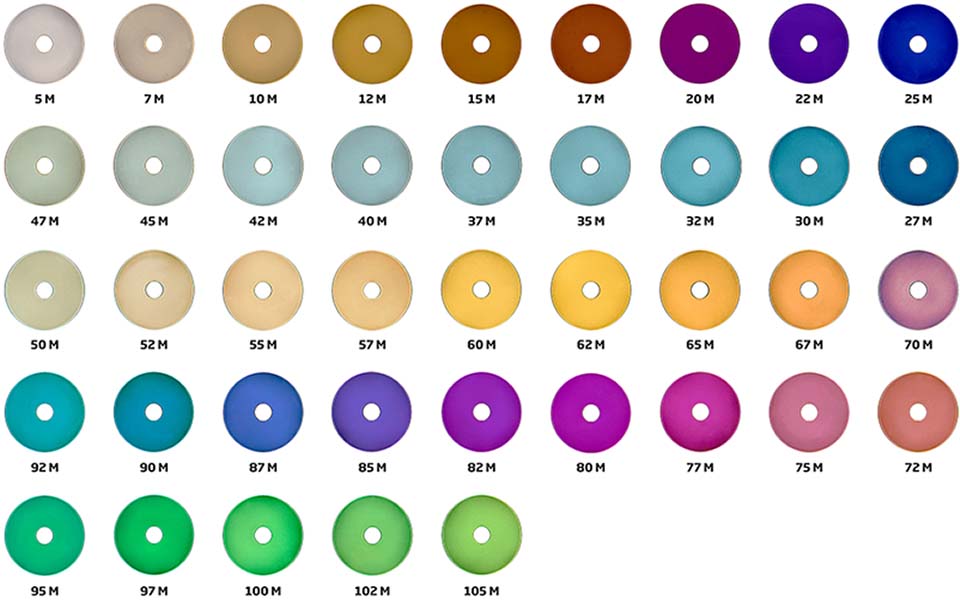

Possible colors with TioCol™ color anodizing

The colors in the above overview are not colorfast and may deviate.