TioCol™ systems for color anodizing of titanium and titanium alloys

In color anodized implants and components, a flawless and homogeneous appearance is an attractive and compelling quality feature. This requires a stable and reproducible electrochemical process that allows the targeted build-up of an oxide layer on the cleaned titanium or titanium alloy components.

With KKS TioCol™ color anodizing systems, oxide layer thicknesses between 10 and 300 nanometers can be achieved reproducibly through exact implementation of the process parameters. Oxide layers in this thickness range cause an interference effect that makes the surfaces appear in a wide spectrum of colors (shiny or matte). Through precisely adjustable process control, KKS TioCol™ color anodizing systems guarantee reproducible and homogeneous coloring.

Application of KKS color anodizing systems

- Implants and accessories such as screws, plates, intramedullary nails, etc.

- Dental implants (connections) and related components

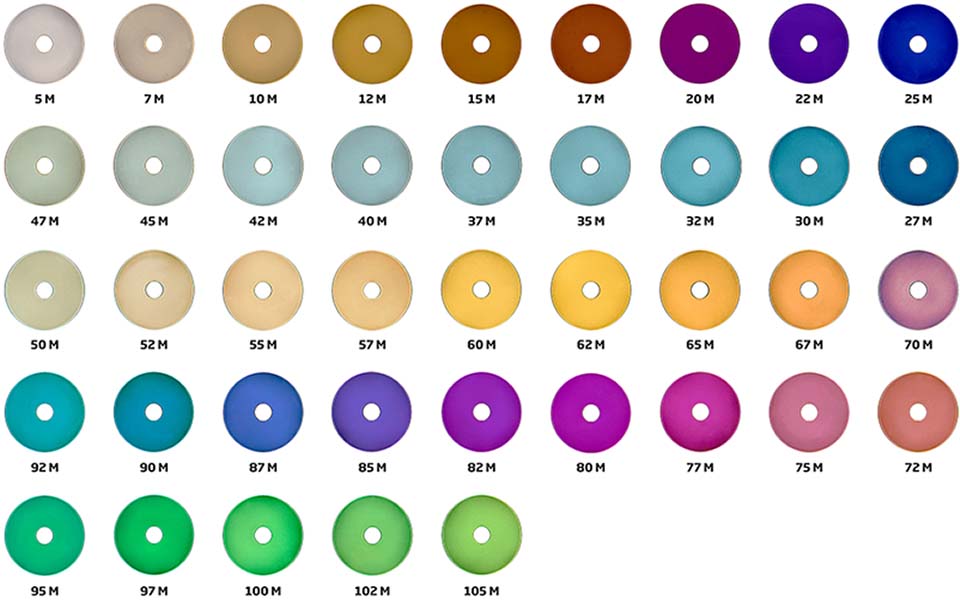

KKS TioCol™ color palette

Using the KKS TioCol™ process and KKS color anodizing systems, colors can be produced according to the TioCol™ color palette. All colors can be made “shiny” or “matte” through different pretreatments. To achieve the defined colors, all process parameters and process steps must be adhered to precisely. Correct control of the rectifier and an optimum voltage curve profile are also crucial. Other parameters for a perfect result include monitoring of the liquid agents for surface treatment and their temperature and the correct pick-up and positioning of components.

The colors in the above overview are not colorfast and may deviate.

Properties and applications of KSS TioCol™ color anodizing systems

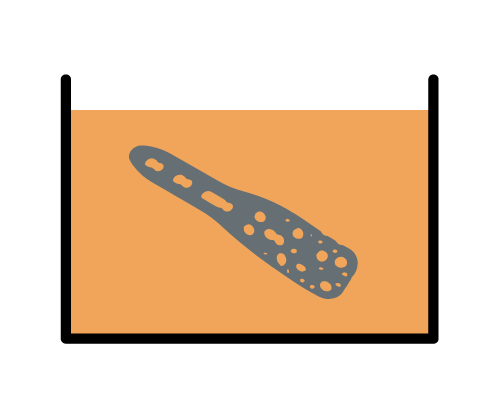

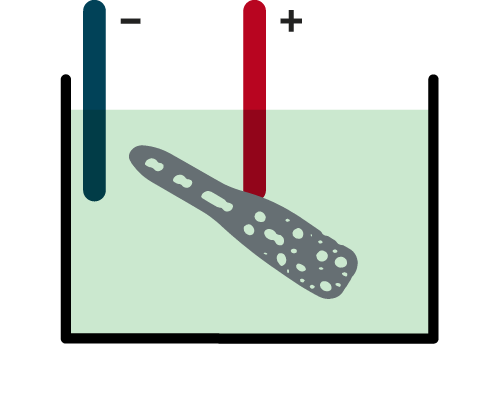

Color anodizing process with a KKS system

KKS anodizing units are of modular design and can be produced as either manual or fully automatic systems. The plants are designed so that the process sequence can be carried out in a single run according to customer-specific requirements. Depending on the requirements, processes such as cleaning, pickling, power rinsing, rinsing and anodizing are coordinated with each other and integrated within a single system. To ensure complete traceability, automatic logging is available for recording all process parameters. To ensure operator safety, in KKS color anodizing systems, a fume extraction unit is additionally installed in the pickling, power rinsing and anodizing tank.

Graphical illustration of process sequence for anodizing titanium (non-exhaustive example)

KKS TioCol™ color anodizing systems

Effective mass/goods window in mm | 300 x 300 x 200 |

Tank capacity in liters (approx.) | 60 |

Rectifier | 150 V / 50 A |

Effective mass/goods window in mm | 400 x 300 x 400 |

Tank capacity in liters (approx.) | 120 |

Rectifier | 150 V / 50 A |

Effective mass/goods window in mm | 500 x 300 x 500 |

Tank capacity in liters (approx.) | 150 |

Rectifier | 150 V / 50 A |

The systems are custom-made and adapted to individual requirements.

TioCol™ color anodizing systems for small parts

With KKS TioCol™ laboratory color anodizing systems, small batches and micro parts can be achieved reproducibly in laboratory environments through exact implementation of the process parameters. Through precisely adjustable and monitored process control, KKS TioCol™ laboratory color anodizing systems guarantee reproducible and homogeneous coloring.

Goods window in mm (L x W x H) | 150 x 150 x 150 |

Adjustment range of the rectifier | 120 V / 10 A |

Operation rectifier "manual" (M) / "programmable" (P) | M / P |

Goods window in mm (L x W x H) | 250 x 200 x 200 |

Adjustment range of the rectifier | 120 V / 16 A |

Operation rectifier "manual" (M) / "programmable" (P) | P |

Goods window in mm (L x W x H) | 250 x 300 x 250 |

Adjustment range of the rectifier | 150 V / 25 A |

Operation rectifier "manual" (M) / "programmable" (P) | P |

The systems are custom-made and adapted to individual requirements.

Peripheral equipment

Whether you require system peripherals such as DI water treatment, integrated heating systems (continuous-flow water heaters, heat exchangers), dehumidification modules for efficient drying or neutralization systems for contaminated exhaust air and wastewater: KKS offers suitable peripheral equipment for color anodizing systems that supports and guarantees safe and efficient process flows.

Qualified color anodizing systems form the basis for successful process validation in the regulated environment

KKS has more than ten years’ experience in the qualification of color anodizing systems. Color anodizing systems are realized mainly on a customer-specific basis. Equipment qualification (DQ/IQ/OQ) and computer system validation of equipment (CSV) can therefore be carried out as part of the project. This parallel approach by KKS offers another major advantage and huge time savings for our customers.