Dry blasting and wet blasting of medical implants

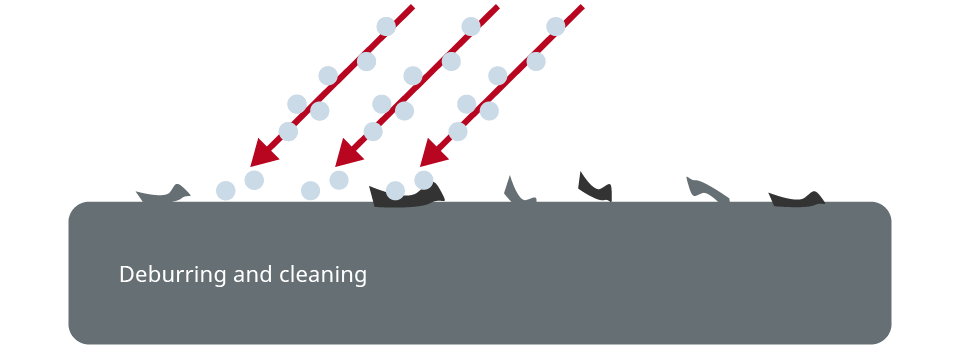

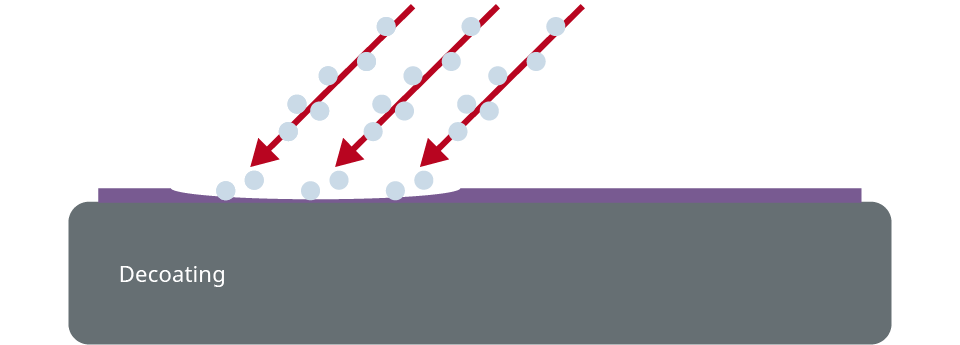

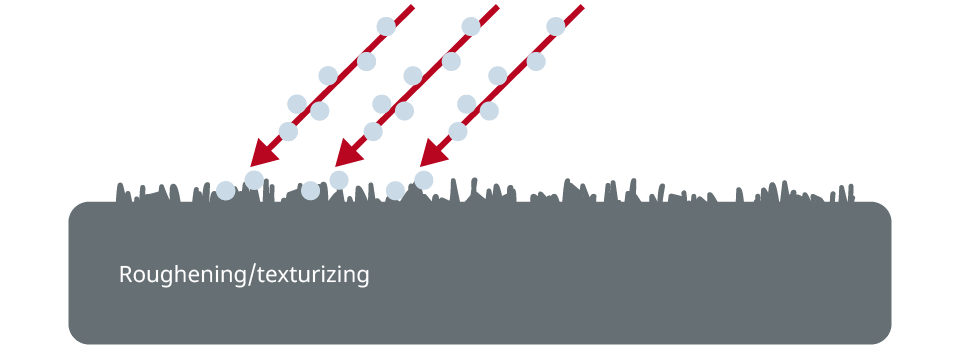

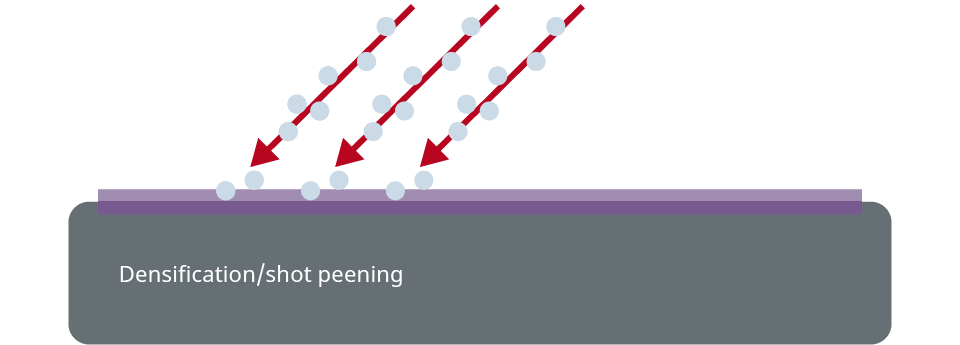

Blasting processes are important surface treatment methods. These processes for texturing surfaces, removing coatings, compensating for irregularities and removing contamination can be abrasive. For example, the surfaces of the cement-free implants and dental implants are highly roughened with blasting media to encourage growth into the bones (osseointegration). However, we can also use media that result in the densification of the material in the boundary areas (plastic deformation), significantly improving the fatigue strength of metal components. Wet blasting also creates surfaces on which fingerprints are invisible, such as for medical instruments.

Blasting – areas of application

Blasting – How it works:

Both dry blasting and wet blasting technology is performed with manual and automatic systems. During dry blasting, the blasting agent is applied directly to the workpiece via a nozzle. We make a distinction here between fine blasting (e.g. with glass beads at low pressure) and coarse blasting (e.g. with corundum at moderate pressure). Ceramic or metal balls and high pressures are typically used for densifying the material of the parts. During wet blasting, the blasting agent is applied to the workpiece using a water jet and the mixture of water and blasting agent is regulated automatically to achieve consistent results.